In today’s fast-growing industrial environment, compressed air systems are widely used for automation and machinery operations. To maintain efficiency and protect equipment, FRL units (Filter, Regulator, and Lubricator) play a vital role. In Ahmedabad, one of India’s strongest industrial hubs, FRLs are in high demand across sectors like textiles, pharmaceuticals, chemicals, engineering, and food processing.

What is an FRL Unit?

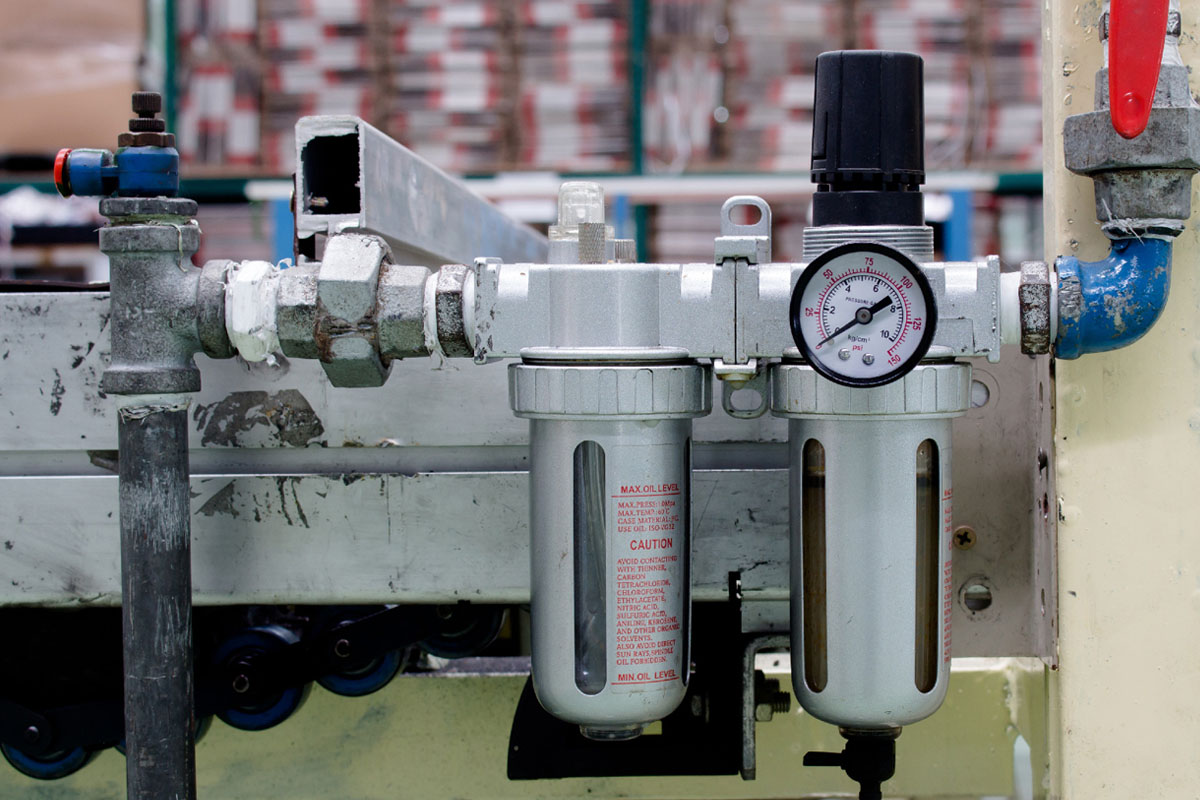

An FRL unit is a combination of three key components used to prepare compressed air before it enters a pneumatic system:

-

Filter – Removes dust, dirt, oil, and moisture from compressed air.

-

Regulator – Maintains a consistent air pressure for smooth machine performance.

-

Lubricator – Provides a fine mist of oil to moving parts, reducing friction and wear.

By using FRL units, industries in Ahmedabad can improve equipment life, reduce breakdowns, and enhance overall productivity.

Importance of FRLs in Ahmedabad Industries

Ahmedabad is home to thousands of industries, many of which rely heavily on pneumatic systems for daily operations. Without proper air treatment, contaminants in compressed air can damage cylinders, valves, and tools. FRL units ensure:

-

Clean and dry compressed air – Preventing rust and corrosion.

-

Stable air pressure – Avoiding damage to sensitive components.

-

Lubricated moving parts – Increasing the service life of pneumatic tools and cylinders.

Key Industry Applications of FRL Units in Ahmedabad:

-

Textile Industry – Smooth operation of looms, dyeing, and finishing machines.

-

Pharmaceuticals – Hygienic and contamination-free air for packaging and processing.

-

Food & Beverage – Maintaining quality standards with clean and regulated air supply.

-

Automotive & Engineering – Ensuring reliability in assembly lines and automation equipment.

-

Chemical Industry – Handling corrosive processes with safe and filtered compressed air.

Types of FRL Units Available in Ahmedabad

Suppliers in Ahmedabad offer a wide range of FRL units to suit various applications:

-

Filter-Regulator (FR) Combinations – Compact units for space-saving setups.

-

Filter-Regulator-Lubricator (FRL) Sets – Standard choice for complete air preparation.

-

Modular FRL Units – Easy to assemble and maintain as per system requirements.

-

Miniature FRLs – Designed for small pneumatic tools and light-duty applications.

Why Choose FRLs from Ahmedabad?

Ahmedabad has become a leading source for FRL units because of:

-

Wide range of manufacturers and distributors – Ensuring availability of standard and customized FRLs.

-

Competitive Pricing – Affordable solutions compared to imports.

-

High Quality Standards – Products designed as per ISO and CE certifications.

-

Quick Delivery & Support – Local suppliers offer fast response and after-sales service.

-

Customized Solutions – FRL units available in different sizes, pressure ratings, and materials.

Factors to Consider Before Buying FRLs

When choosing an FRL unit in Ahmedabad, industries should check:

-

Airflow capacity – To match with the pneumatic system.

-

Operating pressure range – Suitable for your plant operations.

-

Port size – Depending on pipeline and machine requirements.

-

Material & durability – Aluminum, stainless steel, or engineering plastic housings.

-

Ease of maintenance – Replaceable filters and modular construction for long-term use.

Leading FRL Suppliers in Ahmedabad

The city is home to many FRL suppliers, manufacturers, and stockists offering premium brands as well as affordable options. Most suppliers also provide related pneumatic products such as solenoid valves, cylinders, pressure gauges, and fittings. Technical support and after-sales service further make Ahmedabad a trusted hub for air preparation units.

Conclusion

For industries in Ahmedabad, FRL units are an indispensable part of pneumatic automation systems. They ensure clean, regulated, and lubricated air supply, thereby improving efficiency and extending the life of equipment.

If you are looking for FRL suppliers in Ahmedabad, explore local manufacturers who can provide durable, cost-effective, and high-performance FRLs suited to your industry needs. By investing in the right FRL unit, your business can achieve better reliability, reduced downtime, and long-term savings.